How Solar Panels Are Made In 2025

- 14 August 2025

- 26 views

- No Comments

How Solar Panels Are Made In 2025

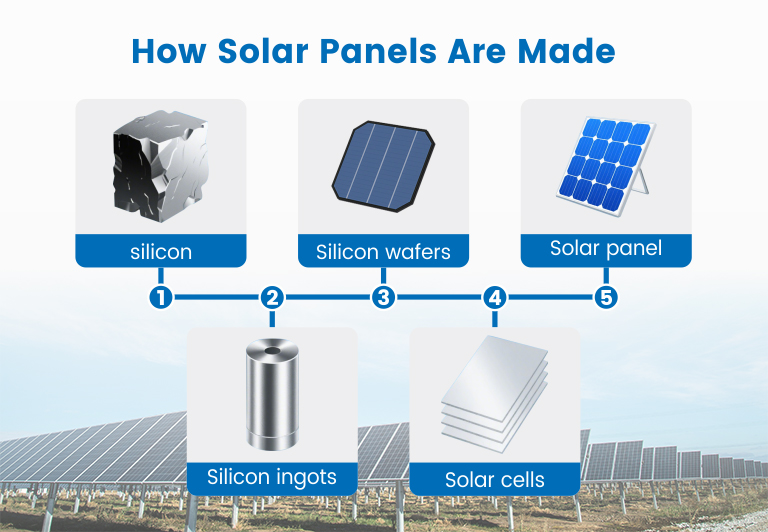

1. The Silicon Journey: From Quartz to Wafers

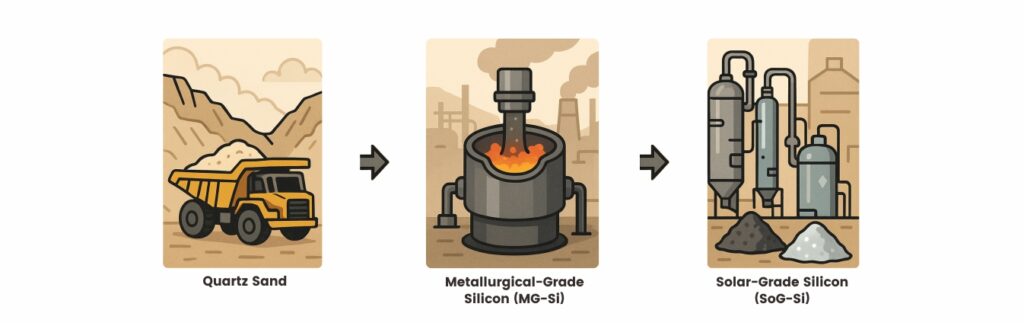

Mining and Purifying Silicon

Every solar panel starts with quartz sand rich in silicon dioxide (SiO₂). Here’s how it becomes solar-grade silicon:

- Mining & Sorting: High-quality quartz sand is selected and freed from impurities.

- Metallurgical-Grade Silicon (MG-Si): The sand is smelted with carbon in an electric arc furnace at over 1,800 °C to reach about 98% purity.

- Solar-Grade Silicon (SoG-Si): Further refined—often via chemical vapor deposition or Siemens process—to reach 99.9999% purity. Even minuscule contaminants can severely impact efficiency.

By 2025, newer low-carbon smelting and silicon recycling methods are cutting both costs and emissions.

Growing Silicon Ingots

Purified silicon is then formed into ingots—either single-crystal or multi-crystalline:

- Czochralski (CZ) Method: A seed crystal dipped into molten silicon is slowly pulled to form a cylindrical single-crystal ingot.

- Casting Method: Molten silicon is poured into square molds to form multicrystalline blocks. It’s cheaper but slightly less efficient.

Hybrid methods that balance efficiency and cost are becoming more common. Recycled silicon is also being integrated into production cycles.

Slicing into Solar Wafers

Ingots are cut into ultra-thin wafers—often under 200 microns thick—using diamond wire saws to minimize waste. Thinner wafers mean less material use and improved light absorption, especially when paired with modern surface texturing.

2. Building the Solar Cell: Turning Wafers into Powerhouses

Doping and the p–n Junction

Silicon alone isn’t enough. It’s “doped” to create:

- n-type layer: Infused with phosphorus (adds extra electrons).

- p-type layer: Infused with boron (creates positively charged holes).

Together, they form a p–n junction where photons excite electrons, creating an electric current.

Light Trapping and Coatings

Fresh silicon reflects sunlight like a mirror. To maximize absorption:

- Micro-texturing with pyramid-like patterns traps light.

- Anti-reflective coatings help cells capture a broader spectrum.

Metallization and Electron Flow

Thin lines of silver or copper—called fingers and busbars—are printed on the wafer to collect electrons. In 2025, many panels use busbar-free designs or transparent conductive materials to boost both efficiency and aesthetics.

3.Types of Solar Cells in 2025

Monocrystalline Silicon Cells

- Efficiency: ~22–27%

- Appearance: Sleek, uniform black

- Lifespan: 25–30 years

Bifacial Panels

Harvest sunlight from both front and back—boosting yield by 10–20% when mounted over reflective surfaces.

Perovskite & Tandem Cells

Perovskite layers stacked on silicon absorb more light, pushing lab efficiency to 34–36% and nearing commercial deployment.

Flexible Thin-Film Panels

Made with CIGS or other thin-film tech, these lightweight, bendable panels are perfect for vehicles, wearable gear, and space-bound uses.

4. How a Solar Panel Is Assembled

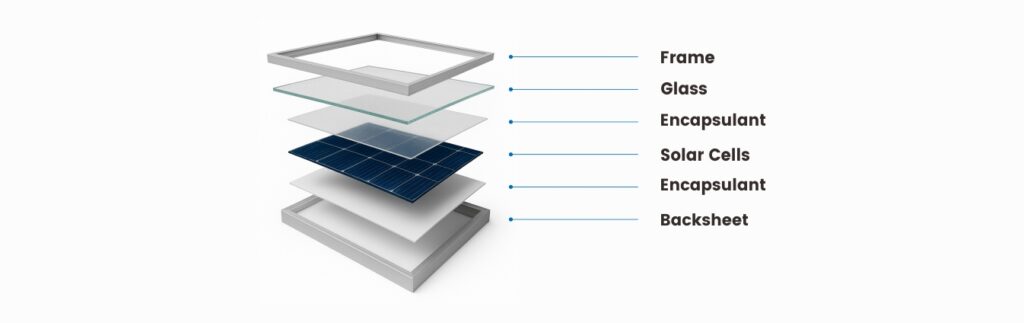

Layer Structure

Typical 2025 solar panel layers:

- Tempered Glass – Hail resistant and durable

- Encapsulant (EVA or POE) – Protects and stabilizes

- Solar Cells – Connected in series

- Backsheet – Moisture and UV shield

- Aluminum Frame – Structural and mountable

Cutting-edge designs now include frameless or glass-glass modules for enhanced longevity and aesthetics. AI-powered quality control detects issues like microcracks during production. The result: energy payback time (EPBT) under two years.

5. Testing, Shipping, and Real-World Installation

Assembly & Testing

Cells are soldered into strings and layered with encapsulant and glass—or dual glass in glass-glass panels. Robots handle laser soldering and shingled cell layout with precision. Panels endure rigorous testing: thermal cycling, UV exposure, humidity, and simulated hail. Electroluminescence imaging and AI inspection catch even microscopic imperfections.

Shipping & Deployment

Panels ship upright in shock- and humidity-monitored crates. They’re found everywhere—from solar shingles on suburban roofs to floating solar farms, dual-axis trackers, and agrivoltaic setups. Lightweight flexible panels power remote vehicles, Arctic bases, and satellites.

The Future of Solar: Recycling, Smart Tech, and Everyday Integration

End-of-Life Recycling Processes

Sustainable practices are catching up fast:

- Frame & Glass Reuse

- Silicon Extraction for New Wafers

- Recovery of Silver & Copper

Forecasts suggest that by 2050, recycled materials could supply half the industry’s silicon and metal needs.

Building-Integrated and Wearable Solar

Solar is going beyond panels:

- Building-Integrated PV (BIPV): Solar windows and façade glass

- Solar Mobility: Vehicles, boats, and remote camps

- Wearable Solar Gear: Backpacks, tents, and more for off-grid power

Pilot projects in cities now feature solar windows, rooftop EV charging, and agrivoltaic-powered farms.

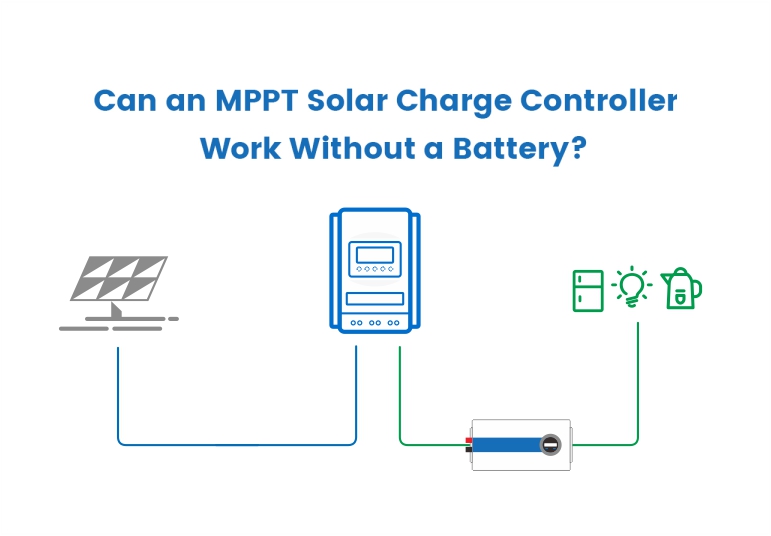

Smart Energy Storage and Monitoring

Panels generate power—but it’s smart storage and conversion systems that make it practical.

EPEVER plays a leading role in this space by providing complete solar system solutions. Their product lineup includes:

- MPPT and PWM Solar Charge Controllers

- Pure Sine Wave Inverters

- Off-Grid Inverters with Built-in MPPT

- Monitoring Devices and Software

- LiFePO₄ Battery Support and Protection Systems

Whether you’re building a solar energy system for a home, RV, farm, or off-grid cabin, EPEVER offers reliable components to maximize your solar investment.

Conclusion: Powering the Future with the Sun

From humble grains of sand to sleek, city-integrated power generators, solar panels tell a story of human ingenuity—driven by efficiency, sustainability, and adaptability. As 2025 unfolds, we’re embracing innovations that sharpen performance, minimize waste, and bring solar into everyday architecture and gear.

Let the sun power your future—cleaner, smarter, and closer to home than ever before.

FAQ

High-purity silicon, tempered glass, EVA/POE encapsulant, silver or copper conductors; plus new materials like perovskite or thin-film in some models.

Most panels last 25–30 years with minor efficiency loss.

Tandem perovskite-silicon cells in lab tests (up to 36%) lead in efficiency, with monocrystalline panels dominating the market.

Yes, including recovery of silicon, silver, copper, glass, and aluminum—recycling is expected to supply up to 50% of raw materials by 2050.